news, people, new vacuum pumps, mergers and acquisition

EBARA launches a new dry vacuum pump for the semiconductor industry

EBARA launches a new dry vacuum pump for the semiconductor industry

December 7, 2016 EBARA CORPORATION will commence the sale of the new model EV-L water-cooled dry vacuum pump for the semi-conductor industry in January 2017. The model EV-L is the optimal dry vacuum pump designed for medium-duty applications such as metal and poly etching. The model EV-L joins the current model EV-S designed for light-duty applications (load lock room, test rigs, PVD equipment, etc.) and model EV-M designed for harsh-duty applications (thin film deposition systems, etc.), completing the line-up of optimal performance dry vacuum pumps .. more |

Agilent Live eSeminars 2016/2017

Agilent Live eSeminars 2016/2017

Join the Agilent vacuum training program: Session 1 – Vacuum Fundamentals Session 2 – Rough Vacuum Pressure Session 3 – High Vacuum Pressure Session 4 – Ultra High Vacuum Since the invention of the VacIon ultra-high vacuum pump over 40 years ago, Agilent (formerly Varian) has maintained a leadership position in vacuum and leak detection technology for scientific and industrial applications. Agilent's highly-regarded training program is staffed by dedicated professional trainers with the expertise and experience to provide comprehensive and thorough instruction on a broad range of vacuum and leak detection technologies. .. more |

Pfeiffer Vacuum introduces new magnetically coupled rotary vane pump Duo 11 ATEX

Pfeiffer Vacuum introduces new magnetically coupled rotary vane pump Duo 11 ATEX

Asslar, Germany, Sept. 28, 2016 The Duo 11 ATEX rotary vane pump, which meets ATEX directive 2014/34/EU, was brought to the market by Pfeiffer Vacuum for processes taking place in potentially explosive atmospheres or conveying explosive gases and vapors .. more |

WABCO Wins Breakthrough Contract from Mahindra & Mahindra

WABCO Wins Breakthrough Contract from Mahindra & Mahindra

Brussels, Belgium - August 3, 2016 WABCO Wins Breakthrough Contract from Mahindra & Mahindra, One of India's Largest Car Makers, to Supply Industry-Leading Vacuum Pumps ; Award Further Enlarges WABCO's Growth Prospects in India more |

Valero Capital Partners announces the acquisition of Vacuum Instrument Corporation

Valero Capital Partners announces the acquisition of Vacuum Instrument Corporation

Ronkonkoma, New York (USA) - June 3, 2016 Valero Capital Partners announces the acquisition of Vacuum Instrument Corporation, a leading provider of tracer gas and air leak detection products, systems and service. This acquisition is in concert with the President, Fritz Ewing and Executive Vice President, John Schreiner announcing their retirements following their remarkable 40 plus year careers building the company. more |

Pfeiffer Vacuum Harmonious Annual General Meeting

Pfeiffer Vacuum Harmonious Annual General Meeting

Asslar, Germany, May 24, 2016 - Vast majority of voting shareholders approve all agenda items - Dividend for 2015 to amount to € 3.20 per share - Beck succeeds Glaum in confirmed supervisory board - Outlook concretized As already disclosed, Pfeiffer Vacuum experienced significant growth in FY 2015 and expects further growth in FY 2016. Manfred Bender, CEO of Pfeiffer Vacuum, remains optimistic for the current year: “Order intake in the year to date has been at a similar level as in the previous year. Since some larger projects should materialize in the second half of the year, we expect FY 2016 sales of approximately 470 million euros. This should coincide with an improvement of operating profit (EBIT). more |

Heritage Global Partners Auction : Assets Formerly of a Pioneering Consumer Electronics & Cell Phone Manufacturer

Heritage Global Partners Auction : Assets Formerly of a Pioneering Consumer Electronics & Cell Phone Manufacturer

Burlingame CA. 94010, USA - May 2016 Auction Sale Featuring Large Quantities of Leybold pumps, Ulvac Pumps, Siemens PLCs, Vacuum Valves, Right Angle Valves.. and more! Starting: May 25th, 2016 10:00 AM PDT Ending: May 26th, 2016 10:00 AM PDT Location: 1576 Rollins Road, Burlingame, CA, USA Preview: May 24th - by appointment only. Auction removal: May 37th - June 3rd, 2016 Large Quantities of Leybold D65B Pumps Large Quantites of Ulvac VD601 Pumps Large Quantities of Siemens Simatic Panels .. more |

NEW VIP200 - Agilent VIP 200 with optimized magnetic field : Ion Pump with best Pumping Speed at 10-8 mbar range

NEW VIP200 - Agilent VIP 200 with optimized magnetic field : Ion Pump with best Pumping Speed at 10-8 mbar range

Leini (Torino), Italy, April 2016 - eXtreme High Vacuum Performance - Versatile & Compact Design - Agilent Quality Thanks to the optimized magnetic field distribution and element design, the VIP 200 is the most compact pump in its category. VIP 200 achieves peak pumping speed in the 10-8 mbar range, the normal operating range for ion pumps, while conventional ion pumps are at peak at higher pressure (10-6 mbar). more |

MDC Vacuum Ltd acquired CVT Ltd., Milton Keynes (UK)

MDC Vacuum Ltd acquired CVT Ltd., Milton Keynes (UK)

Milton Keynes, UK - April 2016 MDC Vacuum Ltd have expanded their manufacturing operations in Europe through the acquisition of CVT Ltd operations based in Milton Keynes. Michael Finch, Partner, Restructuring & Insolvency at Moore Stephens said there had been several interested parties in the purchase of CVT. The pre-packaged sale to MDC was finalised in January. more |

Pfeiffer Vacuum to invest in further growth after a strong FY 2015

Pfeiffer Vacuum to invest in further growth after a strong FY 2015

Asslar, Germany, March 23, 2016 - Total sales of € 451.5 million - EBIT margin at 13.5 percent - Dividend proposal of 3.20 euros - 18–20 million euros investments planned in FY 2016 Manfred Bender, CEO of Pfeiffer Vacuum Technology AG, comments: “The year of our 125th anniversary was a very successful one. After three decreasing years, we were able to increase our sales significantly. The already good profitability was further improved.. more |

Pfeiffer Vacuum introduces leak detection compendium

Pfeiffer Vacuum introduces leak detection compendium

Asslar, Germany, February 29, 2016 Pfeiffer Vacuum has set standards in leak detection for 50 years: with a global range of leak detector solutions since 1966, and using helium or hydrogen as tracer gas. From miniature electronic units to large tanks, from escaping fluids and gases to gas ingress in vacuum systems – the requirements that leak detectors are expected to meet are every bit as varied as the spectrum of industrial products. The extensive range of leak detectors in the Pfeiffer Vacuum portfolio offers solutions for all these requirements.. more |

MKS Instruments Announces Agreement to Acquire Newport Corporation

MKS Instruments Announces Agreement to Acquire Newport Corporation

Andover, Mass., February 23, 2016 - Acquiring an Industry-Leading Technology Company that Serves Common Markets with Complementary Customer Solutions - Expands MKS’ Addressable Market by $4.8 Billion - Strengthens Presence in Key Strategic Markets – Semiconductor, Industrial, Research and Life Sciences - Expected to Realize $35 Million in Annualized Cost Synergies Within 18-36 Months - Expected to be Accretive to MKS’ Non-GAAP Earnings and Free Cash Flow in the First 12 Months Following the Closing MKS Instruments, Inc. (NASDAQ: MKSI), a global provider of technologies that enable advanced processes and improve productivity, and Newport Corporation (NASDAQ: NEWP), a worldwide leader in photonics solutions, announced that they have entered into an agreement for MKS Instruments to acquire Newport Corporation for $23.00 per share. The all-cash transaction is valued at approximately $980 million. .. more |

New modular leak detector ASI 35

New modular leak detector ASI 35

Asslar, Germany - Feb. 11, 2016 The ASI 35 from Pfeiffer Vacuum is a leak detection solution dedicated to leak detection machine builders, system integrators and end-users. This unit combines high reliability and repeatability with maximum uptime. The ASI 35 provides very good performance for tracer gases helium and hydrogen in integral and localizing test procedures or a combination of both. more |

|

SAES Group announces the establishment of a new SAES RIAL Vacuum S.r.l.

Lainate (MI), Italy - Jan. 29, 2016 SAES RIAL Vacuum S.r.l. has the mission to design and manufacture state of the art, high quality vacuum components and integrated systems for accelerators, research systems and industrial equipment. SAES RIAL Vacuum origins from a synergistic pact between SAES Getters S.p.A., RIAL VACUUM RESEARCH and RODOFIL SNC. more |

EBARA launches a new dry vacuum pump for the semiconductor industry

December 7, 2016

EBARA CORPORATION (“EBARA”) will commence the sale of the new model EV-L water-cooled dry vacuum pump for the semi-conductor industry in January 2017.

The model EV-L is the optimal dry vacuum pump designed for medium-duty applications such as metal and poly etching. The model EV-L joins the current model EV-S designed for light-duty applications (load lock room, test rigs, PVD equipment, etc.) and model EV-M designed for harsh-duty applications (thin film deposition systems, etc.), completing the line-up of optimal performance dry vacuum pumps offered for sale across the range, from light-duty to harsh-duty.

The model EV-L is a compact, low power consumption model with corrosion resistant materials employed as standard, and having the optimal temperature profile appropriate for the process application.

Going forward, EBARA will step up its commitment to developing products and services that contribute to our customers’ productivity and total cost reduction.

EBARA Corporation - www.ebara.co.jp

Pfeiffer Vacuum introduces new magnetically coupled rotary vane pump Duo 11 ATEX

Asslar, Germany - Sept. 28, 2016

The Duo 11 ATEX rotary vane pump, which meets ATEX directive 2014/34/EU, was brought to the market by Pfeiffer Vacuum for processes taking place in potentially explosive atmospheres or conveying explosive gases and vapors. As such, it satisfies the most stringent explosion protection requirements.

The ATEX certification applies for both the interior and exterior of the pump.

The Duo 11 ATEX is classified as equipment category 3G and temperature class T4.

It can convey all gases up to and including explosion group IIC.

The pumping speed is 9 m³/h at 50 Hz and 10.5 m³/h at 60 Hz.

The Duo 11 ATEX is equipped with a frictionless magnetic coupling. The shaft seal rings that are used with other rotary vane pumps can be dispensed with as a result. The extra safety which the magnetic coupling provides is important in explosive atmospheres: without shaft seal rings, it is impossible for media inside the pump to escape out through faulty shaft seal rings.

Explosion-proof equipment is required in many types of applications: potentially explosive gases are used in numerous industrial processes.

Hazardous gas atmospheres are present in applications such as research experiments, various industrial processes, biotechnology, and chemistry laboratories. Gas filling machines are also vulnerable to a massive risk of explosion. The new Duo 11 ATEX from Pfeiffer Vacuum can be used in all these areas.

Pfeiffer Vacuum GmbH - www.pfeiffer-vacuum.com

Sabine Neubrand, Tel. +49 6441 802-1223

WABCO Wins Breakthrough Contract from Mahindra & Mahindra

Brussels, Belgium - August 3, 2016

WABCO Holdings Inc. (NYSE: WBC), a leading global supplier of technologies that improve the safety, efficiency and connectivity of commercial vehicles, today reported details of its acquisition of a new customer, Mahindra & Mahindra, one of India's largest manufacturers of passenger cars and sport-utility vehicles.

In a breakthrough multi-year agreement, WABCO will supply vacuum pumps across all Mahindra & Mahindra's major engine platforms, with series production expected to begin in late 2017.

WABCO will supply this original equipment manufacturer (OEM) with industry-leading compact vacuum pumps that feature modular, lightweight design and ultra-low power consumption for braking as well as non-braking functions. This innovative vacuum pump technology enables better fuel economy and reduced emissions. Furthermore, to deliver differentiated service to Mahindra & Mahindra, WABCO's product application and world-class manufacturing will be implemented locally in India.

“Mahindra is empowered and driven to engineer and manufacture passenger cars that are robust, reliable, economy minded and environmentally responsible,” said Mr. Bhupesh Patil, Senior General Manager, Strategic Sourcing, Mahindra & Mahindra. “WABCO's technology leadership in vacuum pumps is consistent with our commitment to innovation, enabling us to achieve automotive breakthroughs and helping us to build cars that thrill their owners.”

“We highly value Mahindra & Mahindra's confidence in our new long-term supply relationship, particularly as we connect WABCO's technology leadership to strengthen this new customer's competitiveness and support their promise to drive the future of passenger cars,” said Mr. P. Kaniappan, Vice President, WABCO INDIA. “This major new supply agreement is also grounded on WABCO's commitment to differentiate through high quality and cost effectiveness, which further enhances WABCO's long-term prospects in this key emerging growth market for passenger cars.”

“Our new multi-year contract with Mahindra & Mahindra once again exemplifies WABCO's technology leadership in vacuum pumps as car manufacturers across the globe increasingly adopt WABCO innovations to boost fuel economy, improve sustainability and further delight their own customers,” said Mr. Kaniappan. “We continually rise to the challenge of setting new standards for vacuum pumps that meet or exceed local specificities for top performance and ultra-low power consumption.”

With more than 50 years of experience in vacuum pump design and production, WABCO currently supplies a global base of passenger car manufacturers.

WABCO (NYSE: WBC) is a leading global supplier of technologies and services that improve the safety, efficiency and connectivity of commercial vehicles. Founded nearly 150 years ago, WABCO continues to pioneer breakthrough innovations for advanced driver assistance, braking, stability control, suspension, transmission automation and aerodynamics. Partnering with the transportation industry as it maps a route toward autonomous driving, WABCO also uniquely connects trucks, trailers, drivers, cargo, and fleet operators through telematics, as well as advanced fleet management and mobile solutions. WABCO reported sales of $2.6 billion in 2015. Headquartered in Brussels, Belgium, WABCO has 12,000 employees in 39 countries.

For more information, visit www.wabco-auto.com

Valero Capital Partners announces the acquisition of Vacuum Instrument Corporation

Ronkonkoma, New York (USA) - June 3, 2016

Valero Capital Partners announces the acquisition of Vacuum Instrument Corporation, a leading provider of tracer gas and air leak detection products, systems and service. This acquisition is in concert with the President, Fritz Ewing and Executive Vice President, John Schreiner announcing their retirements following their remarkable 40 plus year careers building the company.

Fritz Ewing, retiring President said, “From the beginning VIC has been a pioneer in providing state of the art leak detection systems for diverse applications and industries, including Automotive, HVAC, Medical, Research and others. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the satellites we launch into space to the pace makers we insert in our bodies. The ever-increasing worldwide competition for high quality and safe products combined with the new leadership of the company will ensure its growth and continuing success. I couldn’t be more optimistic for the future of the company.”

They leave behind a legacy of technology and product innovation, operations and quality excellence as well as superlative customer relationships.

“I am pleased to be able to pass Vacuum Instrument to new leadership that is knowledgeable in the industry and dedicated to moving the company to new levels. I know our many long time employees will prosper with the new ownership,” added John Schreiner, retiring Executive Vice President.

The company, now named Vacuum Instruments Corporation, LLC will continue to manufacture high quality products and service its customers as it has done historically, building on the strong foundation laid by Mr. Ewing and Mr. Schreiner.

Jim Pelusi, Chairman of VIC, LLC remarked, “We look forward to growing upon the legacy that Fritz, John and the management team have built over the past years. We inherit a strong foundation of leak detection know-how, a deep understanding of customer applications and strong customer relationships. These attributes provide a wonderful platform to add new and innovative offerings to improve our customers’ operations.”

Vacuum Instruments Corporation, LLC provides a wide variety of leak detection solutions from standard products to custom designed systems, offering a wide array of flexible configurations to suit its customers’ demanding needs, serving a variety of industries such as Automotive, Aerospace and Defense, and Semiconductor Manufacturing.

“The ownership, management and employees of Vacuum Instrument have built an industry leader over the years that offers market differentiated products and unparalleled customer service. I am excited about joining the team and working in concert with our customers, suppliers, partners and employees to continue to deliver superior value to the market,” commented Jeff Plante, CEO.

For further information:

Vacuum Instruments Corporation, LLC - www.vicleakdetection.com

- 2099 Ninth Avenue, Ronkonkoma, New York 11779, USA

email: Sales@VICLeakDetection.com, Tel. +1 631 737 0900

Pfeiffer Vacuum Harmonious Annual General Meeting

Asslar, Germany, May 24, 2016

- Vast majority of voting shareholders approve all agenda items

- Dividend for 2015 to amount to € 3.20 per share

- Beck succeeds Glaum in confirmed supervisory board

- Outlook concretized

Today the Annual General Meeting of Pfeiffer Vacuum Technology AG took place in the town hall of Wetzlar, Germany.

The meeting's attendance amounted to 61.33 percent of voting rights. Some 390 guests attended the event and were guided through the agenda by Dr. Michael Oltmanns, the Chairman of the Supervisory Board. The vast majority of represented shareholders approved all agenda items which were voted on. As a result, a dividend of € 3.20 per share will be paid out on May 25. This corresponds to a total amount of € 31,576,508.80.

Filippo Th. Beck will succeed Wilfried Glaum, who did not run for reasons of age, in the Supervisory Board. The other Supervisory Board members were confirmed in their functions. Dr. Michael Oltmanns will remain the Supervisory Board's head.

As already disclosed, Pfeiffer Vacuum experienced significant growth in FY 2015 and expects further growth in FY 2016.

Manfred Bender, CEO of Pfeiffer Vacuum, remains optimistic for the current year: “Order intake in the year to date has been at a similar level as in the previous year. Since some larger projects should materialize in the second half of the year, we expect FY 2016 sales of approximately 470 million euros. This should coincide with an improvement of operating profit (EBIT). We regard this as a conservative assessment which could be influenced by positive project decisions of our customers.”

Order intake in the 1st quarter of 2016 amounted to € 117.4 million.

Pfeiffer Vacuum Technology AG - www.pfeiffer-vacuum.com

- Berliner Str. 43, 35614 Aßlar, Deutschland

Eerik Budarz, Investor Relations, email: Eerik.Budarz@pfeiffer-vacuum.de, Tel. +49 6441 802 1346

Heritage Global Partners Auction : Assets Formerly of a Pioneering Consumer Electronics & Cell Phone Manufacturer

Burlingame CA. 94010, USA - May 2016

Auction Sale Featuring Large Quantities of Leybold pumps, Ulvac Pumps, Siemens PLCs, Vacuum Valves, Right Angle Valves.. and more!

Starting: May 25th, 2016 10:00 AM PDT

Ending: May 26th, 2016 10:00 AM PDT

Location: 1576 Rollins Road, Burlingame, CA, USA

Preview: May 24th - by appointment only.

Auction removal: May 37th - June 3rd, 2016

Large Quantities of Leybold D65B Pumps

Large Quantites of Ulvac VD601 Pumps

Large Quantities of Siemens Simatic Panels

Large Quanties of: Ametek XSC-1326-89093C isolated milivolt transmitter

Hubbell – Circuit lock – HBL 430 MI7W

VAT 26524-KA11-BKS1

VAT 26524-KA22-BWT1

VAT 26524-KA12-BKS1

VAT 26524-KA21-BWT1

VAT Valve – A-151-4249 01234-KA24-AVV1

MKS MFC GE50A001203RBV010 Range : 2000 SCCM Gas Helium

Pepperl Fuchs KFD2/CRG2/1.D

CHNT NB1-D4

CHNT NB1-D10

IFM SM6004

IFM SM8004

MKS 901P Load Lock Transducer

MKS I-Baratron Digital Manometer Model DMB12TGACINH54

BURKERT 2875 00236925 with Burkert 00178355

stainless steel flexible bellows..

Heritage Global Partners, Inc. - www.heritageglobalinc.com

- 1576 Rollins Road, Burlingame CA. 94010, USA

David Barkoff, Director of Sales, email: dbarkoff@hginc.com, Tel. +1 650 759 2242

NEW VIP200 - Agilent VIP 200 with optimized magnetic field : Ion Pump with best Pumping Speed at 10-8 mbar range

Leini (Torino), Italy, April 2016

Thanks to the optimized magnetic field distribution and element design, the VIP 200 is the most compact pump in its category.

VIP 200 achieves peak pumping speed in the 10-8 mbar range, the normal operating range for ion pumps, while conventional ion pumps are at peak at higher pressure (10-6 mbar).

eXtreme High Vacuum Performance :

- Maximum pumping speed at low pressure (10-8 mbar range)

- Best in class pumping speed for Nitrogen and Argon

- Reduced outgassing through Vacuum Firing thermal treatment

- New Diode and Noble Diode element design (more cells vs Volume)

- StarCell element: superior performance and stability for Noble gases.

- Optimized magnetic field distribution gives higher pumping speed

Versatile & Compact Design

- The smallest size in its category

- Wide range of configurations available, including side port and different HV feed throughs

- New heater design allows for high thermal efficiency and easy mounting operation

- Pumping elements fully replaceable

Agilent Quality

- Recognized Technology & Market leadership from the Ion Pump inventor: «All innovations introduced by Agilent in Ion Pump technology have become the standard in the industry»

- High standards of Manufacturing Excellence

- High reliability and performance guaranteed by severe test methodology

Agilent Technologies Italia SpA - www.vacuum-choice.com

- via F.lli Varian 54 - 10040 Leini (Torino), Italy

email: vpt-customerservice@agilent.com, Tel: +39 011 9979 111, Toll free: 00 800 234 234 00

MDC Vacuum Ltd acquired CVT Ltd., Milton Keynes (UK)

Milton Keynes, UK - April 2016

MDC Vacuum Ltd have expanded their manufacturing operations in Europe through the acquisition of CVT Ltd operations based in Milton Keynes.

Michael Finch, Partner, Restructuring Insolvency at Moore Stephens said there had been several interested parties in the purchase of CVT. The pre-packaged sale to MDC was finalised in January.

CVT Ltd is a long established designer and manufacturer of specialist ultra-high vacuum vessels and precision mechanisms. The company operates from a 20,000 sq. ft. factory in Milton Keynes.

MDC Vacuum Products LLC, based in Hayward, California, was founded in 1975 and is a leading provider of high vacuum and ultra-high vacuum vessels, ceramic-to-metal bonding and gas delivery.

MDC recently launched a multi-million dollar group-wide initiative to restructure the business and position the company for long term stable growth.

“It's exciting times here at MDC: we’re investing in the latest technology and tools, expanding our capabilities and skill sets, and kicking off a global focus on continual innovation..

I want MDC to be the low cost, high quality, innovator in the vacuum business. We aim to delight our customers with exceptional service combined with outstanding products” said Roger Cockroft, MDC's CEO.

For more information please contact:

MDC Vacuum Limited - www.cvt.ltd.uk

- 4 -7 Carters Lane, Kiln Farm, Milton Keynes, MK11 3ER, United Kingdom

email: sales@mdcvacuum.eu, Tel. +44 (0)1908 563 267

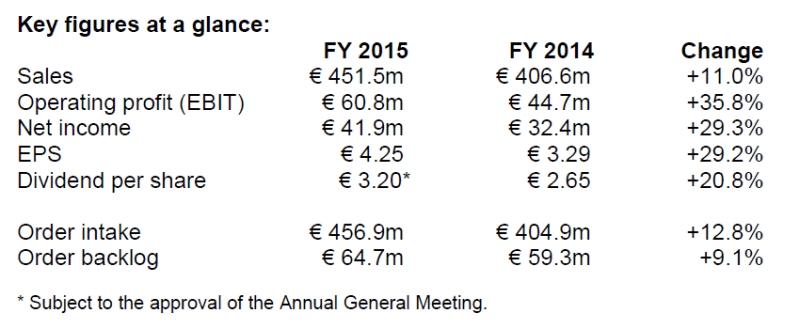

Pfeiffer Vacuum to invest in further growth after a strong FY 2015

Asslar, Germany, March 23, 2016

- Total sales of € 451.5 million

- EBIT margin at 13.5 percent

- Dividend proposal of 3.20 euros

- 18–20 million euros investments planned in FY 2016

Total sales for FY 2015, which had been preliminarily announced and have meanwhile been audited, amounted to € 451.5 million. This represents an increase of 11.0 percent (previous year: € 406.6 million).

Operating profit (EBIT) grew 35.8 percent and amounted to € 60.8 million (previous year: € 44.7 million).

As a result, the operating profit margin (EBIT margin) for FY 2015 amounted to 13.5 percent and, thus, was 2.5 percentage points higher than the previous year's figure of 11.0 percent.

The Management and Supervisory Boards propose a dividend of € 3.20 per share (previous year: € 2.65). The payout ratio therefore would amount to around 75 percent of consolidated net income.

|

Order intake for FY 2015 amounted to € 456.9 million (prior year: € 404.9 million). This resulted in a book-to-bill ratio of 1.01 for FY 2015 (prior year: 1.00). Year-end FY 2015 order backlog amounted to € 64.7 million (year-end FY 2014: € 59.3 million).

Manfred Bender, CEO of Pfeiffer Vacuum Technology AG, comments: “The year of our 125th anniversary was a very successful one. After three decreasing years, we were able to increase our sales significantly. The already good profitability was further improved. All market segments contributed to this growth. The best development was seen in the Semiconductor and Analytics markets.

In order to let shareholders participate in this positive development, Management and the Supervisory Board will propose a dividend of € 3.20 per share at the AGM in May. The investment in our company shall remain worthwhile for all shareholders in the future.”

In context of regional sales,

Europe posted a slight increase of 2.1 percent to € 187.0 million (previous year: € 183.2 million).

In Asia, sales rose 16.3 percent to € 151.5 million (previous year: € 130.3 million).

Even more pleasing was the development in the Americas where sales increased by 21.3 percent to € 112.4 million (previous year: € 92.6 million).

Sales of turbopumps rose disproportionately by 16.1 percent to € 144.8 million (previous year: € 124.7 million).

Revenues from backing pumps increased by 14.5 percent to € 102.4 million (previous year: € 89.4 million).

Business with instruments and components expanded by 1.9 percent to € 98.8 million (previous year: € 96.9 million).

Service revenues rose by 13.8 percent to € 96.7 million (previous year: € 85.0 million).

Finally,systems sales amounted to € 8.8 million after € 10.6 million in the previous year.

All markets exhibited growth in the reported year 2015:

The Semiconductor market produced sales of € 139.9 million (previous year: € 118.4 million) – this represents an increase of 18.1 percent.

In the heterogeneous market segment Industry there was a sales increase of 7.3 percent to € 115.0 million (previous year: € 107.2 million).

Sales in the Analytical market segment rose disproportionately by 16.6 percent to € 91.7 million (previous year: € 78.7 million).

The Research and Development market segment increased its sales to € 55.6 million (previous year: € 55.2 million).

Coating sales grew by 4.7 percent and amounted to € 49.3 million (previous year: € 47.1 million).

Gross profit for the reporting period amounted to € 175.5 million (previous year: € 143.4 million). This meant that the gross profit margin increased by 3.6 percentage points to 38.9 percent (previous year: 35.3 percent).

The operating profit (EBIT) amounted to € 60.8 million. It was 35.8 percent above the previous year's figure of € 44.7 million. This corresponds to an operating profit margin (EBIT margin) of 13.5 percent (previous year: 11.0 percent).

The financial result increased to € -0.3 million (previous year: € -0.5 million) and the tax rate amounted to 30.7 percent (previous year: 26.8 percent). This resulted in net income of € 41.9 million which represents an increase of 29.3 percent (previous year: € 32.4 million). Earnings per share amounted to € 4.25 (previous year: € 3.29), representing an increase of 29.2 percent.

Despite the payment of the high dividend, Pfeiffer Vacuum was able to increase its net cash position to € 94.7 million as at December 31, 2015 (previous year: € 70.3 million). The equity ratio rose to 67.3 percent (previous year: 65.2 percent).

With reference to the motto of our annual report that has been published today, we have been thinking further:

Concretization of mid-term planning

Pfeiffer Vacuum's goal is the continuation of its successful growth path in the years to come. Significant potential is seen in both areas Semiconductor/Coating and Analytics/Industry. By consistently aligning the business units Semiconductor/ Coating and Analytics/Industry towards customer demand and global growth trends like increasing digitalization, renewable energy and population growth, Pfeiffer Vacuum will sustainably benefit from these dynamics. The company expects the business unit Semiconductor/Coating to grow by an average of 5–7 percent per year over the cycle and Analytics/Industry to exhibit an average of 3–5 percent growth per year over the cycle.

First implementation success of GAP already in 2015

In order to create the prerequisites for profitable growth on an operational level, Pfeiffer Vacuum initiated its GAP program last year. The goals of GAP are the optimization of operational processes and the establishment of more efficient structures. The emphasis of GAP is on key account management, the optimization of the supply chain, and the alignment of production towards a competency center approach. GAP's main measures are aimed towards being realized by the end of 2017 while some have already been successfully put into effect during the past financial year 2015.

Advanced investment planning in order to increase capacity

The optimization of Pfeiffer Vacuum's production is a further goal for sustainable growth. The company‘s comprehensive investment plan includes the enlargement of its machine park and in this context the expansion of existing production locations or the establishment of new ones. In this context, additional capital expenditures in the amount of 6–8 million euros have been planned for the current fiscal year 2016.

Active use of the strong balance sheet to seize opportunities for acquisitions

In addition to the operational measures, Pfeiffer Vacuum plans to use its financial strength in order to foster the company's long-term growth through selective acquisitions. Potential targets must fulfill strict internal criteria and can arise from the current consolidation process within the industry or from adjacent relevant markets.

Outlook 2016

For the FY 2016 Pfeiffer Vacuum expects a noticeable increase in sales compared to FY 2015. This is expected to coincide with a noticeable improvement in operating profit and the EBIT margin compared to FY 2015.

Pfeiffer Vacuum Technology AG - www.pfeiffer-vacuum.com

- Berliner Str. 43, 35614 Aßlar, Deutschland

Eerik Budarz, Investor Relations, email: Eerik.Budarz@pfeiffer-vacuum.de, Tel. +49 6441 802 1346

Pfeiffer Vacuum introduces leak detection compendium

Asslar, Germany, February 29, 2016

From miniature electronic units to large tanks, from escaping fluids and gases to gas ingress in vacuum systems – the requirements that leak detectors are expected to meet are every bit as varied as the spectrum of industrial products. The extensive range of leak detectors in the Pfeiffer Vacuum portfolio offers solutions for all these requirements.

Experience counts!

In 2016, Pfeiffer Vacuum is celebrating 50 years of its leak detectors.

Founded in 1890, the company is a leading global manufacturer of components and systems for generating, measuring and analyzing vacuum and detecting leaks.

It was in 1966 that the first helium leak detector ASM 4 designed and engineered in-house was patented and launched. The launch of this product was an important milestone for the industry.

The first leak detector with an integrated turbopump, the ASM 110, followed in 1985. This technology represented an important advance in the design of the devices that were available on the market at that time. The first portable leak detector, dubbed the ASM 310, was then launched in 2009.

Extensive choice of leak detectors with helium or hydrogen tracer gas

Today, Pfeiffer Vacuum can rightly maintain with pride that its leak detectors find every leak. No leak is too small or too large to go undetected.

Dr. Matthias Wiemer, member of the Management Board of Pfeiffer Vacuum Technology AG, said:

“Pfeiffer Vacuum is the only company that offers such an extensive portfolio of leak detectors using helium or hydrogen as a tracer gas for a broad spectrum of use. Pfeiffer Vacuum develops and produces leak detectors and helium recovery systems for applications requiring a guaranteed high production throughput as well as leak-tight parts. Our qualified expert staff supports customers in selecting the best solution to meet their requirements.”

Pfeiffer Vacuum introduces leak detection compendium

The “Leak Detection Compendium” from Pfeiffer Vacuum provides extensive expertise on leak detection and leak testing. Leak detectors and systems, as well as various leak detection measures, are described for readers looking for a hands-on approach. The contents of the compendium are easy to understand and written with users in mind. Diagrams and photos illustrate the subjects discussed. Numerous tips from expert users on the subject of leak detection and leak testing provide readers with support with their particular application. Clearly arranged tables facilitate the conversion of units of measure and other everyday leak detector tasks. The handbook itself also stands out with its clear structure and layout.

Dr. Matthias Wiemer explains: “We are proud to introduce the leak detection compendium as a unique practical aid to support our customers with their work.

It brings together concentrated expertise in a handy pocket-sized book – from describing the various tracer gases and explaining various leak detection methods right up to showing helpful examples from practical use.”

Thanks to close collaboration with customers and the continuous focus on their needs, Pfeiffer Vacuum is constantly optimizing and expanding the portfolio. During the past months the following innovations have been introduced to the market:

ASM 340 – Leak detection even at 100 hPa

The ASM 340 is a powerful and sturdy leak detector for reliable quality assurance. The wide spectrum of use extends from industrial and analytic applications to research and development and the coatings market. This compact leak detector is for use both in serial production as well as for maintenance tasks. It is available with conventional or dry pumps as well as in a version without a backing pump. The ASM 340 can be used for qualitative localization of leaks as well as for quantitive integral or local testing. It stands out with its powerful vacuum system which guarantees extremely quick operational readiness. It also excels with a fast response time due to the high helium pumping speed. These features are responsible for short cycle times and a high part throughput. The ASM 340 is the only leak detector of its class on the market that is able to localize leaks even at 100 hPa.

ASI 35 modular leak detector

The ASI 35 from Pfeiffer Vacuum is the ideal solution for integration into industrial leak detector systems. This leak detector combines high performance, reliability and repeatability with maximum rung time. With helium or hydrogen as a tracer gas, it provides excellent performance during integral and localizing testing methods as well as in a combination of the two. Its great flexibility makes this leak detector ideal for demanding testing tasks with extremely low background signals and guarantees short overall throughput times. The device can be used for leak detection in various operating modes in vacuum testing or sniffing tests at the maximum sensitivity. The ASI 35 allows an extremely high throughput and guarantees precise and repeatable results plus extremely short cycle times of only 1 second during leak detection. With its high performance in sniffing operation, the ASI 35 is particularly well suited for sniffing leak detection at several points.

The electronic module was designed for universal voltage, which makes the ASI 35 easy to integrate into systems intended for global use.

The leak detector is also suitable for conditions with ambient temperatures of up to 45°C. Easy mechanical integration is enhanced by a wide spectrum of interfaces allowing data logging and full external operation of the system.

AMI 120 leak testing system for pharmaceutical blister packs

The AMI 120 from Pfeiffer Vacuum is a unique in-process system for non-destructive leak testing of pharmaceutical blister packs.

This innovative solution allows highly sensitive quantitative leak testing to be carried out in real time and without the use of a special tracer gas. The penetration of moisture, oxygen or microbiological materials can considerably impair the quality of drugs. Even minuscule leaks in the packaging, with holes in the range of a a micron can impair the stability of the drug. With the AMI 120, qualified by leading pharmaceutical companies, the leak rate can be measured within a cycle time of less than 45 seconds even from 1/10 ìm. The test system has its own calibration facility using traceable test leaks. This ensures that the AMI 120 always works reliably. It uses a patented process for in-house process control during leak testing of blister packs. The AMI 120 is easy to set and is more sensitive and faster than conventional testing methods. The system is compliant with standard CFR21, Part 11, and is extremely affordable since it does not need to work with a special tracer gas. The integrity test is suitable for all types of blister packs.

Pfeiffer Vacuum GmbH - www.pfeiffer-vacuum.com

Sabine Neubrand, Tel. +49 6441 802-1223

MKS Instruments Announces Agreement to Acquire Newport Corporation

Andover, Mass., February 23, 2016

- Acquiring an Industry-Leading Technology Company that Serves Common Markets with Complementary Customer Solutions

- Expands MKS’ Addressable Market by $4.8 Billion

- Strengthens Presence in Key Strategic Markets – Semiconductor, Industrial, Research and Life Sciences

- Expected to Realize $35 Million in Annualized Cost Synergies Within 18-36 Months

- Expected to be Accretive to MKS’ Non-GAAP Earnings and Free Cash Flow in the First 12 Months Following the Closing

Andover, Mass., February 23, 2016 – MKS Instruments, Inc. (NASDAQ: MKSI), a global provider of technologies that enable advanced processes and improve productivity, and Newport Corporation (NASDAQ: NEWP), a worldwide leader in photonics solutions, today announced that they have entered into an agreement for MKS Instruments to acquire Newport Corporation for $23.00 per share. The all-cash transaction is valued at approximately $980 million.

The combined company is expected to have approximately $1.4 billion in pro forma annual revenue, based on the two companies’ 2015 historical results. The transaction is expected to be accretive to MKS Instruments’ Non-GAAP net earnings and free cash flow during the first 12 months post-closing. The combined company expects to realize $35 million in annualized cost synergies within 18 to 36 months and anticipates revenue synergies from the expansion of MKS Instruments’ served addressable markets and leverage of complementary sales channels.

“The combination of MKS Instruments and Newport Corporation creates a premier supplier of critical components and subsystems for a diverse set of growing end markets, each with a common need for highly precise technology enabling solutions,” said Gerald Colella, MKS Instruments’ Chief Executive Officer and President.

“This acquisition is consistent with our strategy to pursue sustained profitable growth by expanding into adjacent markets while increasing our served addressable market in our core semiconductor business. Our shared customer requirements and complementary technologies together with our increased scale will enable us to lead in our served markets, deliver innovative and cost-effective solutions for our customers, and drive profitable growth.”

“This combination represents a great outcome for all of Newport's stakeholders,” said Robert Phillippy, President and Chief Executive Officer of Newport Corporation.

“The complementary nature of the two companies’ technologies and customer base will create exciting opportunities for our employees, and enable the combined company to deliver innovative solutions to our customers. We look forward to working closely with the MKS Instruments team to ensure a smooth transition.”

MKS Instruments intends to fund the transaction with a combination of available cash on hand and up to $800 million in committed debt financing. The combined company will maintain a very strong balance sheet, with combined pro forma net cash and investments on hand of approximately $425 million.

The transaction has been approved by MKS Instruments’ and Newport Corporation's board of directors and is subject to customary approvals, including regulatory and approval by Newport Corporation's shareholders, and is expected to close in the second quarter of 2016.

Lazard acted as financial advisor to MKS Instruments. JP Morgan acted as financial advisor to Newport Corporation.

For more information please contact:

Newport Corporation - www.newport.com

- 1791 Deere Avenue, Irvine, CA 92606, USA

Seth H. Bagshaw, Vice President, Chief Financial Officer and Treasurer, Tel. +1 978.645.5578

Monica Gould, Investor Relations, email: monica@blueshirtgroup.com, Tel. +1 212.871.3927

Pfeiffer Vacuum reports significant growth in FY 2015

Asslar, February 19, 2016

- Sales at € 451.5 million

- EBIT amounts to € 60.8 million

- Incoming orders at € 456.9 million

Pfeiffer Vacuum announces preliminary figures for FY 2015.

According to unaudited numbers, FY 2015 sales amounted to € 451.5 million, an increase of 11.0 percent compared to the previous year's € 406.6 million.

This surpasses the sales guidance previously given by the company. EBIT amounted to € 60.8 million (prior year: € 44.7 million).

This corresponded to an EBIT margin of 13.5 percent for FY 2015 (previous year: 11.0 percent).

Order intake for FY 2015 amounted to € 456.9 million (prior year: € 404.9 million). This resulted in a book-to-bill ratio of 1.01 for FY 2015 (prior year: 1.00). Year-end FY 2015 order backlog amounted to € 64.7 million (year-end FY 2014: € 59.3 million).

Manfred Bender, CEO of Pfeiffer Vacuum Technology AG, comments:

“The year of our 125th anniversary was a very successful one. After three decreasing years, we were able to increase our sales significantly. The already good profitability was further improved. All market segments contributed to this growth. The best development was seen in the Semiconductor and Analytics markets. Despite the currently mixed market sentiment, we expect growth to continue in FY 2016.”

The complete audited results will be announced on the day of the financial press conference which is scheduled for March 23, 2016.

Pfeiffer Vacuum Technology AG - www.pfeiffer-vacuum.com

- Berliner Str. 43, 35614 Aßlar, Deutschland

Eerik Budarz, Investor Relations, email: Eerik.Budarz@pfeiffer-vacuum.de, Tel. +49 6441 802 1346

New Pfeiffer Vacuum modular leak detector ASI 35

Asslar, Germany - Feb. 11, 2016

- Highest performance in helium and hydrogen

- Reliable, fast and sensitive

- For industrial leak detection systems

The ASI 35 from Pfeiffer Vacuum is a leak detection solution dedicated to leak detection machine builders, system integrators and end-users. This unit combines high reliability and repeatability with maximum uptime. The ASI 35 provides very good performance for tracer gases helium and hydrogen in integral and localizing test procedures or a combination of both. Therefore, it offers flexibility in testing of demanding samples with minimum signal background and crosstalk providing for fast overall cycle times.

Due to its modular design, the ASI 35 is optimized for minimum space requirements and maximum integration options. The user interface is optional since the unit can be controlled by PC or PLC. Only two cables are needed to connect the vacuum and electronic modules, making the ASI 35 an easy leak detector to set up.

Further advantages of the ASI 35 are its low maintenance turbopump for high helium pumping speed, its dual independent long life filaments as well as its state of the art electronics. These features guarantee a long lasting trouble free operation. The leak detection system can be designed for testing in various operational modes for vacuum or sniffing tests with the highest sensitivity level. The ASI 35 sustains very high throughput and ensures the accuracy and reproducibility of the measurement results as well as fast cycle times as short as 1 second. Thanks to its performances in sniffing, the ASI 35 is the perfect leak detector especially if multipoint sniffing is needed.

The electronic module is suitable for universal voltage, making it easy to integrate the ASI 35 into systems designated for worldwide operation. The leak detector is designed for working conditions in ambient temperatures of up to 45 °C.

Easy mechanical integration is complemented by a wide range of interfaces allowing data acquisition and complete external control of the system. Thanks to customized I/O configuration, a basic version of this leak detector can be operated without a PC or PLC.

Pfeiffer Vacuum GmbH - www.pfeiffer-vacuum.com

Sabine Neubrand, Tel. +49 6441 802-1223

SAES Group announces the establishment of a new SAES RIAL Vacuum S.r.l.

Lainate (MI), Italy - Jan. 29, 2016

SAES RIAL Vacuum S.r.l. has the mission to design and manufacture state of the art, high quality vacuum components and integrated systems for accelerators, research systems and industrial equipment.

SAES RIAL Vacuum origins from a synergistic pact between:

SAES Getters S.p.A., a worldwide leader in the production and development of pumps and innovative getter solutions for ultra-high vacuum for research, accelerator facilities and industry

RIAL VACUUM RESEARCH (trade mark of RODOFIL), specialized in the design and manufacture of equipment, vacuum components, ultra- high vacuum systems and cryogenic equipment

RODOFIL SNC, specialized in precision machining using wire and sinker EDM, CNC milling and turning, advanced manufacturing techniques.

The newly established Company combines, at the highest degree, SAES Getters skills in material science, vacuum technology and innovation with experience of design, assembly and hi-tech mechanical machining of RIAL and RODOFIL to provide excellent products and quality.

For these reasons, SAES RIAL Vacuum is uniquely positioned to offer competitive advantages to the vacuum community, as well to support customer's innovation through its technological know-how.

For more information please contact:

SAES RIAL Vacuum S.r.l. - www.saesgetters.com

- Via Tito ed Ettore Manzini, 7/a - 43126 Parma

Dr. Paolo Manini, email: p.manini@saesrial.com, Tel. +39 0521 949311

news

news

neu

neu

actu

actu

Diary conferences meetings exhibitions

Directory manufacturers suppliers

E-Proc / Projects

Career job search, offers,

Your Press Release are you lauching a new product ? did your company built a new plant ? delivered an important piece of equipment? agreed to a distribution agreement ?

email your press release to info@vacuum-guide.com

home vacuum-guide.com