- 49630 Pontiac Trail, Wixom MI 48393-2009, USA

email, Tel.

ALD-Holcroft Vacuum Technologies Co., Inc. was formed in 2005 as a joint venture between ALD Vacuum Technologies of Hanau, Germany, and AFC-Holcroft of Wixom, Michigan. ALD is a world-renowned company in the field of vacuum furnace equipment and has been in business for over 60 years. AFC-Holcroft is a global leader in the supply of atmosphere based furnace systems and has a history reaching back more than 90 years.

Our world renound product line is comprised of the:

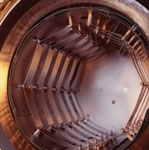

- MonoTherm: high flexibility, single chamber vacuum furnaces

- DualTherm & DualTherm-Q: high performance, dual chamber furnaces for HPGQ or VOQ

- ModulTherm: high throughput, automated vacuum furnace systems

- SyncroTherm: high profits, one-piece-flow can be synchronized with part machining or operate in the fast-batch mode for high speed processing of small batches.