Vacuum snow removal / Schneeabsaugung von einsturzgefährdeten Flachdächern

Vacuum snow removal / Schneeabsaugung von einsturzgefährdeten FlachdächernJan. 2011 Neben der traditionellen Maßnahme – mit Schaufel und Schippe – oder dem Hubschraubereinsatz gibt es nun eine erprobte Alternative: Die bundesweit tätige Firma JobLuft Service GmbH saugt mit ihren riesigen Vacuum-LKW Schnee und Eis einfach von den Dächern ab. Dies geschieht ähnlich wie beim Staubsauger. „Wir können auch noch dann agieren, wenn die maximale Dachlast fast erreicht ist, da außer einem Schlauch keine weiteren Maschinen oder Trupps von Arbeitern auf das Dach müssen“, argumentiert die Firma. Bis zu 70 Meter Gebäudehöhe und Dachflächen von mehreren 10.000 Quadratmetern sind kein Problem für die Spezialisten. more |

World's Largest Vacuum Chamber to Test Orion

World's Largest Vacuum Chamber to Test OrionJune 2007 Before NASA's new spacecraft, Orion, carries the next generation of explorers into space, it first will make a shorter journey to the world's largest vacuum chamber. In this massive, cathedral-like structure, it must endure a variety of rigorous challenges. Called the Space Power Facility, the vacuum chamber resides at NASA Glenn Research Center's Plum Brook Station in Sandusky, Ohio. It measures 100 feet in diameter and towers at 122 feet tall. Its immense size and ability to simulate the vacuum of space make it ideal for testing the Orion crew exploration vehicle. more |

Air cooled Vacuum System for Bottling at Carlsberg - Tuborg, DK

Air cooled Vacuum System for Bottling at Carlsberg - Tuborg, DKNov. 2005 The Danish beer producer Carlsberg - Tuborg contacted Pneumofore to solve the bacteriological contamination problems in the beer filling process. more |

Airbus A310 cruising at simulated 33.000 feet

Airbus A310 cruising at simulated 33.000 feetSept. 2005 The 'Fraunhofer Institut' near Munich in Germany is presently testing a A310 with three UV50 pumps from Pneumofore. more |

|

Vacuum snow removal

www.aquar.ag |

|

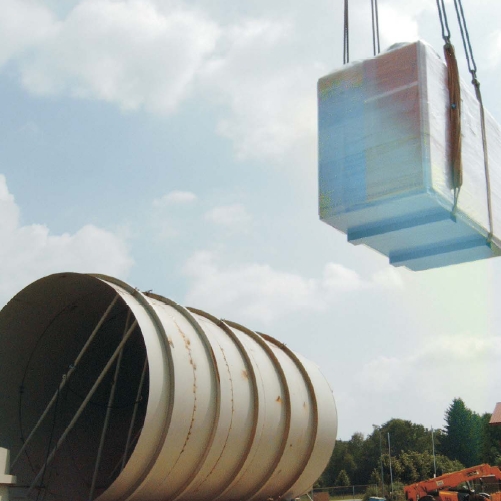

World's Largest Vacuum Chamber to Test Orion

America will send a new generation of explorers to the moon aboard NASA’s Orion crew exploration vehicle. Making its first flights early in the next decade, Orion is part of the Constellation Program to send human explorers back to the moon, and then onward to Mars and other destinations in the solar system. A component of the Vision for Space Exploration, Orion’s development is taking place in parallel with missions to complete the International Space Station using the space shuttle before the shuttle is retired in 2010. Before NASA's new spacecraft, Orion, carries the next generation of explorers into space, it first will make a shorter journey to the world's largest vacuum chamber. In this massive, cathedral-like structure, it must endure a variety of rigorous challenges. Called the Space Power Facility, the vacuum chamber resides at NASA Glenn Research Center's Plum Brook Station in Sandusky, Ohio. It measures 100 feet in diameter and towers at 122 feet tall. Its immense size and ability to simulate the vacuum of space make it ideal for testing the Orion crew exploration vehicle. On June 11, the facility opened its doors for a rededication ceremony. Agency managers, community stakeholders and elected officials gathered to celebrate the role this facility will play in the country's next phase of space exploration. Making its first flights early in the next decade, Orion is part of NASA's Constellation Program to send human explorers back to the moon and then onward to Mars and other destinations in the solar system. The fully assembled spacecraft will stand 75 feet tall and include a crew module to carry the astronauts; a service module to provide power, propulsion and communications; a launch abort system for emergency escapes; and an adapter to connect the spacecraft to its launch system. But before NASA can launch Orion, the agency "must demonstrate that the vehicle is capable of withstanding the harsh environment of space," said Robert Moorehead, Director of Space Flight Systems at Glenn. "The Space Power Facility will help us do that." In 2008, workers will begin modifying the building to accommodate these tests. A new vibration and acoustic test chamber, a mechanical vibration test stand and electromagnetic interference equipment will enable the facility to simulate the conditions Orion must endure on its mission. "The Space Power Facility will be the only facility in the U.S., if not the world, that can perform complete environmental testing on a fully assembled spacecraft," said David Stringer, director of Plum Brook Station. The new reverberant acoustic chamber will subject Orion to the intense vibrations and shockwaves it will endure during launch and ascent. In the vacuum chamber, infrared lamps and cold walls flushed with liquid nitrogen will simulate the extreme hot and cold temperatures of space. The electromagnetic interference tests will also take place inside the vacuum chamber, which blocks radio frequencies and cell phone signals. Electromagnetic interference equipment positioned on moving platforms will challenge the reliability of Orion's communications and electronics systems. Built in 1969, the Space Power Facility has tested the International Space Station's radiator and solar arrays, the Mars rover landing systems, and most of the nation's major rockets, including Atlas and Delta. With the upgrades, the Plum Brook facility also will be well suited to test next-generation lunar landers, robotic systems, and military and commercial spacecraft. "Plum Brook will have an important role to play in the future exploration of space," said NASA's Associate Deputy Administrator Charles Scales. "It's hard to believe that in less than two decades, people will look up and, with nothing but a strong telescope, see the shining lights of a research center on the moon." Jan Wittry (SGT, Inc.), NASA's Glenn Research Center, www.nasa.gov fact sheet, space power facility |

|

Largest Vacuum Chillers in operation in China - Nanjing and Caojing, China images images images images Croll-Reynolds recently delivered three high vacuum chillers with associated steam jet-ejector vacuum systems to petrochemical plants in Nanjing and Caojing, China. The three systems are the largest vacuum chillers operating in China. They were designed by Croll Reynolds USA and built at fabrication facilities in China. Critical components were sourced from CR locations offshore. Croll-Reynolds' local representatives were responsible for management of manufacturing, installation and commissioning. Croll-Reynolds Chill-Vactor vacuum chillers are ejector-driven systems with no major moving parts. This results in minimal maintenance and low operating cost. In vacuum chillers, water literally cools itself when exposed to the proper vacuum. No refrigerant is required. Croll-Reynolds' Chill Vactor employs the principle of evaporative cooling. Evaporation is essentially a cooling process. To accelerate the process it is performed under vacuum and completed in a number of stages. Croll-Reynolds Company, Inc. - www.croll.com - 751 Central Avenue, P.O. Box 668, Westfield, NJ 07901, USA Henry Hage, email: hhage@croll.com, Tel. +1 (908) 232-4200 |

|

Air cooled Vacuum System for Bottling at Carlsberg - Tuborg, DK

The Danish beer producer Carlsberg - Tuborg contacted Pneumofore to solve the bacteriological contamination problems in the beer filling process. The improvement also had to reduce power consumption, noise level and offer additional advantages in terms of constant vacuum level via full integration in the process control system, with all over reduced life cycle cost of the entire solution. Not an easy task, it took years of research, especially due to beer turning into foam under vacuum. However, the motivation was huge, since the environmental inspectors would not allow further presence of bio active components in the cooling water system of the previously installed liquid ring vacuum pumps. Solving Problems Having the Pneumofore UV H pumps the operational temperature of 110 deg.C or more, all evacuated volatile bacteria passing through the pump are all killed. No germs are present at the exhaust of the UV pump and the separated bottling liquid, in this case beer, is recovered with the dedicated CIP liquid separator installed ahead of the UV pump. Other tests done with rotary vane pumps did fail due to insufficient oil temperature within the vacuum pump to destroy the germs. Evacuated gases must pass through the pump without depositing sedimentation on vanes and other machine components. The vacuum level shall be optimised for highest bottling speed, tests are run down to 50 mbar abs. in case of glass containers. Another expense of beer bottling plants is caused by the flushing of hollow glass with the CO2 gas, which gets lost in the vacuum system, but might be recovered to further reduce the payback time of the innovative UV pump solution. The constant vacuum level is managed by means of a PID valve, controlled by a simple button, no matter which ambient temperature The danger of strict food regulations appliance, which potentially stop the production or cause at least enormous fines or high cooling liquid waste treatment, is now under control in the plant of Fredericia, DK. Furthermore, based on the collected measured data, the economical savings, which are secondary to the hygienic issues in this food industry, are simply calculated considering that the yearly saved water quantity is 35.000 m3 and the yearly saved electrical energy is 42.000 kWh. Not all vacuum bottling systems run with water ring vacuum pumps, still this engineered UV solution also attracts users of oil sealed ring pumps, due to lowest return of investment duration. PNEUMOFORE Vacuum - www.pneumofore.com - Via N. Bruno, 34, 10090 - Rivoli (Torino), Italy Cathrine Tveen Hansen, Marketing Manager, email: vacuum@pneumofore.com, Tel. +39 (011) 950 40 30, Fax +39 (011) 950 40 40 |

|

Airbus A310 cruising at simulated 33.000 feet of altitude

The 'Fraunhofer Institut' near Munich in Germany is presently testing the effect of sudden flight height variations with an Airbus A310. The site is open to public and generated interest also at Boeing, Alenia and more. The three UV50 Pneumofore vacuum pumps have a total capacity of 10.000 m3/h (270 KW). They are driven by frequency inverters from 35 - 65Hz and simulate altitudes up to 33.000 feet. The pumps are air cooled and run only a few hundred hours per year. The vacuum pumps were started in September 2005. PNEUMOFORE Vacuum - www.pneumofore.com - Via N. Bruno, 34, 10090 - Rivoli (Torino), Italy Cathrine Tveen Hansen, Marketing Manager, email: vacuum@pneumofore.com, Tel. +39 (011) 950 40 30, Fax +39 (011) 950 40 40 |

Are you lauching

a new product ?

a new application ?

Did your company built

a new plant ?

delivered an important

piece of equipment?

contact us and publish your report: info@vacuum-guide.com